Novinky z oboru

-

Co je polyethylen (PE)?

Polyethylen (PE), také známý jako polyethylen nebo polyethene, je jedním z nejběžněji používaných plastů na světě. Polyethyleny mají obvykle lineární strukturu a jsou známé jako adiční polymery. Primárním použitím těchto syntetických polymerů je obalový materiál. Polyethylen se často používá k výrobě plastových sáčků, lahví, plastových fólií, kontejnerů a geomembrán. Je třeba poznamenat, že ročně se pro komerční a průmyslové účely vyrobí přes 100 milionů tun polyethylenu. -

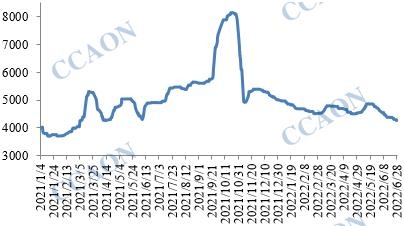

Analýza fungování exportního trhu s PVC v mé zemi v první polovině roku 2022.

V první polovině roku 2022 se exportní trh s PVC meziročně zvýšil. V prvním čtvrtletí, které bylo ovlivněno globální ekonomickou recesí a epidemií, mnoho domácích exportních společností uvedlo, že poptávka po externích discích byla relativně snížena. Od začátku května se však s ohledem na zlepšení epidemické situace a řadu opatření zavedených čínskou vládou na podporu hospodářského oživení zvýšila provozní míra domácích podniků vyrábějících PVC, exportní trh s PVC se oživil a poptávka po externích discích vzrostla. Čísla vykazují určitý růstový trend a celková výkonnost trhu se ve srovnání s předchozím obdobím zlepšila. -

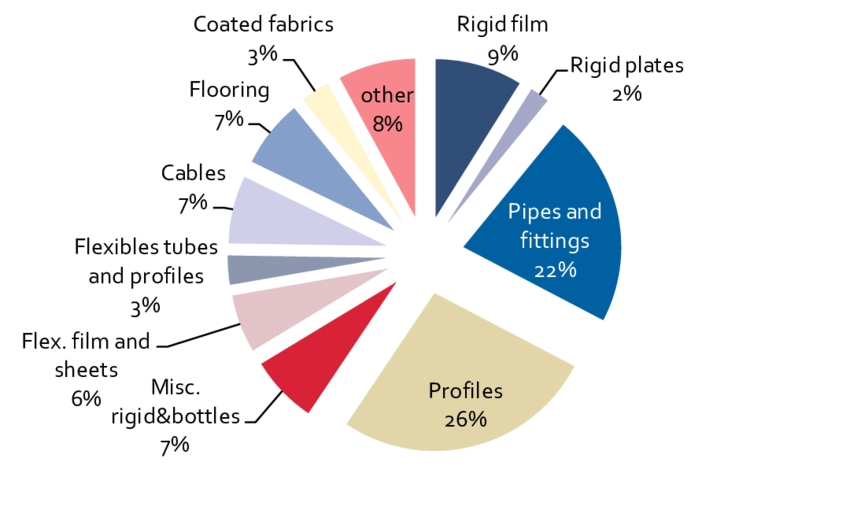

K čemu se PVC používá?

Ekonomický a všestranný polyvinylchlorid (PVC neboli vinyl) se používá v různých aplikacích ve stavebnictví, zdravotnictví, elektronice, automobilovém průmyslu a dalších odvětvích, od potrubí a obkladů, krevních vaků a hadiček až po izolaci drátů a kabelů, součásti systémů čelního skla a další. -

Projekt rozšíření rafinerie Hainan o milion tun etylenu a rafinace se brzy předá.

Projekt rafinace a chemické výroby ethylenu v Hainanu a projekt rekonstrukce a rozšíření rafinace se nacházejí v zóně ekonomického rozvoje Jang-pchu s celkovou investicí přesahující 28 miliard juanů. Celkový pokrok ve výstavbě dosáhl 98 %. Po dokončení projektu a uvedení do výroby se očekává, že přinese více než 100 miliard juanů do navazujících odvětví. Fórum o diverzifikaci olefinových surovin a high-end downstream se bude konat v San-ji ve dnech 27. a 28. července. V nové situaci bude diskutován rozvoj velkých projektů, jako je PDH a krakování etanu, budoucí trend nových technologií, jako je přímá přeměna ropy na olefiny, a nová generace uhlí/methanolu na olefiny. -

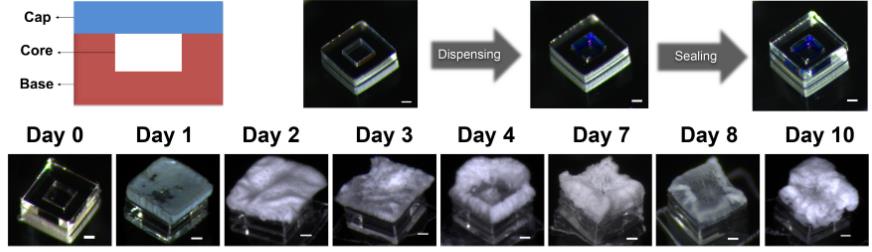

MIT: Mikročástice kopolymeru polymléčné a glykolové kyseliny vytvářejí „samoregulační“ vakcínu.

Vědci z Massachusettského technologického institutu (MIT) v nedávném publikování časopisu Science Advances informují, že vyvíjejí jednorázovou samoočkovací vakcínu. Po injekčním podání do lidského těla může být vakcína uvolňována opakovaně bez nutnosti posilovací dávky. Očekává se, že nová vakcína bude použita proti nemocem od spalniček až po Covid-19. Uvádí se, že tato nová vakcína je vyrobena z částic poly(laktid-ko-glykolové kyseliny) (PLGA). PLGA je degradovatelná funkční polymerní organická sloučenina, která je netoxická a má dobrou biokompatibilitu. Byla schválena pro použití v implantátech, stezích, opravných materiálech atd. -

Yuneng Chemical Company: První průmyslová výroba stříkatelného polyethylenu!

Nedávno jednotka LLDPE v Polyolefinovém centru společnosti Yuneng Chemical Company úspěšně vyrobila DFDA-7042S, stříkatelný polyethylenový produkt. Je zřejmé, že stříkatelný polyethylenový produkt je produktem odvozeným od rychlého rozvoje technologie následného zpracování. Speciální polyethylenový materiál s povrchovou úpravou stříkaným povrchem řeší problém špatné barevné vlastnosti polyethylenu a má vysoký lesk. Produkt lze použít v dekorativních a ochranných oblastech, je vhodný pro dětské výrobky, interiéry vozidel, obalové materiály, ale i pro velké průmyslové a zemědělské skladovací nádrže, hračky, silniční zábradlí atd. a má značné tržní vyhlídky. -

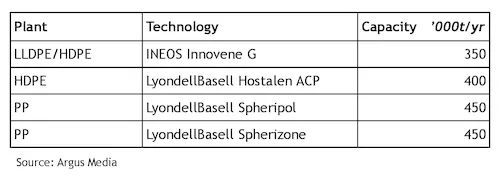

1,65 milionu tun polyolefinů od Petronasu se brzy vrátí na asijský trh!

Podle nejnovějších zpráv společnost Pengerang v Johor Bahru v Malajsii 4. července znovu spustila svou jednotku na výrobu lineárního nízkohustotního polyethylenu (LLDPE) s kapacitou 350 000 tun/rok, ale dosažení stabilního provozu jednotky může chvíli trvat. Kromě toho se od tohoto měsíce očekává nárůst provozu také u závodu na výrobu polypropylenu (PP) s technologií Spheripol s kapacitou 450 000 tun/rok, závodu na výrobu vysokohustotního polyethylenu (HDPE) s kapacitou 400 000 tun/rok a závodu na výrobu polypropylenu (PP) s technologií Spherizone s kapacitou 450 000 tun/rok. Podle odhadu společnosti Argus je cena LLDPE v jihovýchodní Asii bez daně k 1. červenci 1360–1380 USD/tuna CFR a cena tažení PP drátu v jihovýchodní Asii k 1. červenci 1270–1300 USD/tuna CFR bez daně. -

Cigarety v Indii přecházejí na biologicky rozložitelné plastové obaly.

Zákaz 19 druhů jednorázových plastů v Indii vyvolal změny v jejím cigaretovém průmyslu. Ještě před 1. červencem indičtí výrobci cigaret změnili své předchozí konvenční plastové obaly na biologicky rozložitelné plastové obaly. Tabákový institut Indie (TII) tvrdí, že jeho členové byli konvertováni a používané biologicky rozložitelné plasty splňují mezinárodní normy i nedávno vydanou normu BIS. Tvrdí také, že biodegradace biologicky rozložitelných plastů začíná v kontaktu s půdou a přirozeně se biologicky rozkládá při kompostování, aniž by zatěžovala systémy sběru a recyklace pevného odpadu. -

Stručná analýza fungování domácího trhu s karbidem vápenatým v první polovině roku.

V první polovině roku 2022 domácí trh s karbidem vápníku nepokračoval v trendu širokých výkyvů z roku 2021. Celkový trh se pohyboval blízko cenové hranice a byl vystaven výkyvům a úpravám v důsledku dopadu surovin, nabídky a poptávky a podmínek navazujících produktů. V první polovině roku nedošlo k žádnému novému rozšíření kapacity domácích závodů na výrobu PVC metodou karbidu vápníku a nárůst poptávky na trhu s karbidem vápníku byl omezený. Pro chlor-alkalické podniky, které nakupují karbid vápníku, je obtížné dlouhodobě udržovat stabilní zátěž. -

V PVC reaktoru petrochemického giganta na Blízkém východě došlo k výbuchu!

Turecký petrochemický gigant Petkim oznámil, že večer 19. června 2022 došlo v závodě Aliaga k výbuchu. K nehodě došlo v reaktoru PVC továrny, nikdo nebyl zraněn, požár byl rychle uhašen, ale jednotka PVC může být kvůli nehodě dočasně odstavena. Událost může mít větší dopad na evropský spotový trh s PVC. Uvádí se, že vzhledem k tomu, že cena PVC v Číně je mnohem nižší než cena domácích produktů v Turecku a spotová cena PVC v Evropě je vyšší než v Turecku, většina PVC produktů Petkim se v současné době vyváží na evropský trh. -

Společnost BASF vyvíjí plechy do trouby s PLA povlakem!

Dne 30. června 2022 se společnosti BASF a australský výrobce potravinářských obalů Confoil spojily, aby vyvinuly certifikovanou kompostovatelnou papírovou misku na potraviny s dvojitou funkcí, vhodnou do trouby – DualPakECO®. Vnitřek papírové misky je potažen materiálem BASF ecovio® PS1606, což je vysoce výkonný univerzální bioplast komerčně vyráběný společností BASF. Jedná se o obnovitelný biologicky odbouratelný plast (70% obsah) smíchaný s produkty BASF ecoflex a PLA, který se speciálně používá k výrobě povlaků na papírové nebo kartonové obaly na potraviny. Mají dobré bariérové vlastnosti vůči tukům, kapalinám a pachům a mohou snižovat emise skleníkových plynů. -

Aplikace vláken kyseliny polymléčné na školní uniformy.

Společnost Fengyuan Bio-Fiber spolupracuje se společností Fujian Xintongxing na aplikaci polymléčného vlákna na školní oblečení. Jeho vynikající absorpce vlhkosti a schopnost odvodu potu je 8krát vyšší než u běžných polyesterových vláken. PLA vlákno má výrazně lepší antibakteriální vlastnosti než jakékoli jiné vlákno. Odolnost proti kroucení vlákna dosahuje 95 %, což je výrazně lepší než u jakéhokoli jiného chemického vlákna. Kromě toho je tkanina vyrobená z polymléčného vlákna šetrná k pokožce a odolná proti vlhkosti, hřeje a je prodyšná, dokáže také potlačit bakterie a roztoče a je nehořlavá a ohnivzdorná. Školní uniformy vyrobené z této tkaniny jsou ekologičtější, bezpečnější a pohodlnější.